Schmiederad GmbH

How it all began

Due to our presence at the Essen Motor Show 2011, where thanks to Hankook we got the opportunity to present our vehicles to the public and, because we had made a name for ourselves as a supplier of top quality performance parts, we were contacted by the company GEWE/Zerra.

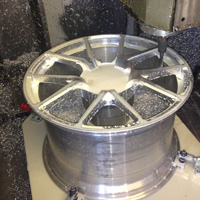

A partner was sought who had the technical capabilities to manufacture forged wheels. We enthusiastically took up this challenge and, with targeted investments in know-how and technology, created the conditions to expand our business field with TIKT Schmiederad GmbH.

Due to its size and flexibility, our company is ideally equipped to fill niches such as the production of forged wheels.

Why Schmiederad?

For the same size, a forged wheel has greater stability than a conventional light alloy wheel made of cast aluminum - while at the same time weighing less. This is made possible on the one hand by the exclusive use of materials of the highest quality and on the other hand by the special manufacturing steps.

The production of a forged wheel is much more complex and can only be done by specialized companies. With our know-how we are able to produce extremely light, beautiful and specially designed wheels according to the requirements for sporting use.

Our forged wheels don't just look fast when stationary - thanks to their low weight and optimized brake ventilation, they also cut a fine figure on the track. The minimization of rotating and unsprung masses has a direct effect on drivability and lap times.

Safety

- Development in cooperation with renowned engineering office

- All forging wheels have a complex TÜV approval

Quality

- All important production steps are carried out in-house

- High vertical range of manufacture leads to outstanding quality

Exclusivity

- We are proud to serve with TIKT Schmiederad GmbH a small but fine market

- Sporty elegance, performance and quality are combined into a unique product

Technology

Forged wheel vs alloy wheels

The production